Offshore Engineer - October 2009

Offshore Engineer - October 2009Friday, November 27, 2009

Friday, October 30, 2009

Casio ClassPad 300

Sunday, October 11, 2009

Friday, October 2, 2009

CASIO Scientific Calculator

Sunday, August 9, 2009

Magazine

Monday, July 13, 2009

Thursday, June 11, 2009

Magazine June 2009

Monday, June 8, 2009

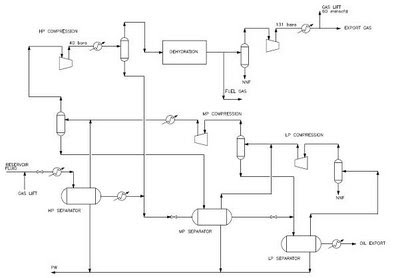

Gas Compression at Offshore (Part 1)

- Gas Export

- Gas Injection to well

- Gas lift

- Fuel gas

Reciprocating Compressor

Continue with:

Gas Compression at Offshore (part 2)

Wednesday, June 3, 2009

Asian Oil and Gas Magazine

Tuesday, May 5, 2009

Friday, May 1, 2009

Artificial Lift

Beam Pumps

Also called as Donkey Pumps ,are most common artificial lift system used in land based. A motor drives a reciprocating beam, connected to a polished rod passing into the tubing via a stuffing box. The sucker rod continues down to the oil level and is connected to a plunger with a valve.

On each upward stroke, the plunger lifts a volume of oil up and through the wellhead discharge. On the downward stroke it sinks (it should sink, not be pushed) with oil flowing though the valve.

Advantages:

- Can be used for wide range production capabilities

- Can produce most wells to depletion at limited rates and depths

- Highly reliable and relatively easy to analyse by using several different means

- Corrosion and scale problems easily treated

- Can produce high temperature or viscous oil

- Low cost production operation

Disadvantages:

- Installation not suitable for crooked hole work

- Depth and volume limited by rod weight and strength

- High gas-oil ratio wells as well as sand and paraffin content in production fluids

- Weight and size can prohibit use in offshore installations

Electrical Submerged Pumps (ESPs)

A motor driven centrifugal pump with rotating blades on a shaft on the bottom of tubing.

Advantages:

- Can be operated in deviated or directionally drilled wells although recommended operating position is in straight section of well

- Can be operated in deep wells with small casings

- Very efficient and economical

Disadvantages:

- Narrow producing range

- Large volumes of gas can be destructive to the pump

- Run life adversely impacted by poor quality electric power supply

Gas Lift

High pressure gas is injected into the production fluids within the tubing string. Leads to decrease in the weight of the fluid column and permits the well to flow.

When the gas lift is started up, several gas lift valves must operate in sequence. During the unloading process, the fluid in the annulus between the tubing and the casing is displaced, along with the high pressure injection gas, through the top gas lift valve into the tubing bore.

Advantages:

- Simple to operate

- Equipment used is relatively inexpensive

- Flexible

- Both high volumes and low volumes can be produced

- Effective handling of corrosion and high gas-oil ratio production

- Low operating costs

- Lower failure rate

Disadvantages:

- Source of high pressure gas must be available

- Not cost effective when used for one-well lease or small fields

- Not very effective for producing deep wells where there is high drawdowns or low bottomhole pressures

- Accurate gas measurements are not easily obtained

- Surging flow can be a source of operating problems with surface equipment

Monday, April 6, 2009

Wednesday, March 25, 2009

Earth Hour 2009

Vote for earth.

"I'm just one person, what can I do for global warming..."

..Let us support the earth, the home where we live, for ourself, for next generation future.

Official web: http://www.earthhour.org/home/

Friday, March 20, 2009

FPSO - Armada Perkasa

FPSO - Armada Perkasa sail out from Keppel shipyard, Singapore.

Movie Source: http://bumiarmada.dkm2.com/

website: http://www.bumiarmada.com/

Wednesday, March 4, 2009

Magazine - March 2009

Tuesday, February 24, 2009

Friday, February 20, 2009

Oil Rig / Offshore Structure

Type of design offshore platform subjects to water depth, geology condition and cost effective solution. The various types of offshore platform shown as below:

- Fixed Steel Structure

- Compliant Tower

- Jack-up Platform

- Concrete Gravity Base Structure

- Tension Leg Platform (TLP)

- Semi-submersible Vessel

- Floating Production System

- Spar Platform

1. FIXED STEEL STRUCTURE

The traditional offshore structure consists of weld steel, tubular framework or jacket to support the topside facilities. Piles driven into the seafloor secure the jacket.

The traditional offshore structure consists of weld steel, tubular framework or jacket to support the topside facilities. Piles driven into the seafloor secure the jacket.Modern design with bridge linked jackets tending to favour a separate well head platform, processing platform and accommodation platform due to safety concern.

The Fixed Steel Structures are restricted to shallow water developments with water deep about 1500 ft.

2. COMPLIANT TOWER

Compliant towers are similar to fixed platforms in that they have a steel tubular jacket that is used to support the topside facilities. Unlike fixed platforms, compliant towers yield to the water and wind movements in a manner similar to floating structures. Like fixed platforms, they are secured to the seafloor with piles. The jacket of a compliant tower has smaller dimensions than those of a fixed platform. Compliant towers are designed to sustain significant lateral deflections and forces, and are typically used in water depths ranging from 1,500 to 3,000 ft.

3. JACK-UP PLATFORM

The Jack-up Platform consists of a triangular shaped (sometimes rectangular), box section barge fitted with three (sometimes four) moveable legs which enable the vessel to stand to the seabed in water depths of up to approximately 120 m (400 ft).

4. CONCRETE GRAVITY BASE STRUCTURE

The Concrete Gravity Base Structure have been constructed using a base manufactured from reinforced concrete. The design of base includes void spaces or caissons to provided the structure with a natural buoyancy which will enable it to be floated to field development location. Once on location the void spaces are flooded on the seabed whilst the topside modules are lifted into place. The void spaces then used as storage compartments for crude oil, or filled with permanent iron ore ballast. The colossal weight of concrete structures obviates the need to install foundation piles, hence the name gravity base structure.

5. TENSION LEG PLATFORM (TLP)

A Tension Leg Platform (TLP) is a buoyant platform held in place by a mooring system. The TLP’s are similar to conventional fixed platforms except that the platform is maintained on location through the use of moorings held in tension by the buoyancy of the hull. The mooring system is a set of tension legs or tendons attached to the platform and connected to a template or foundation on the seafloor. The template is held in place by piles driven into the seafloor. This method dampens the vertical motions of the platform, but allows for horizontal movements. TLPs are used in water depths from 1500 ft to 7000 ft.

The "conventional" TLP is a 4-column design which looks similar to a semisubmersible. Proprietary versions include the Seastar and MOSES mini TLPs; they are relatively low cost, used in water depths between 600 and 4,300 feet (200 and 1,300 m). Mini TLPs can also be used as utility, satellite or early production platforms for larger deepwater discoveries.

6. SEMI-SUBMERSIBLE VESSEL

These platforms have twin hulls (columns and pontoons) of sufficient buoyancy to cause the structure to float, but of weight sufficient to keep the structure upright. Semi-submersible platforms can be moved from place to place; can be ballasted up or down by altering the amount of flooding in buoyancy tanks; they are generally anchored by combinations of chain, wire rope and/or polyester rope during drilling and/or production operations, though they can also be kept in place by the use of dynamic positioning. Semi-submersibles can be used in water depths from 200 to 10,000 feet.

7. FLOATING PRODUCTION SYSTEM

FPSO (floating production, storage, and off-loading) vessel is converted from liquid cargo vessel or new built. FPSO equipped with processing facilities and moored to a location.

Basically, Floating Production Systems are ideal solution for

- The field is small and marginal

- The field is isolated and an established pipeline infrastructure does not exist

- The field is located in very deep water where it would not be possible to install a conventional fixed platform

You may interest:

FPSO - Armada Perkasa (youtube)

The Making of FPSO TGT1 (youtube)

The Making of Armada Sterling FPSO (youtube)

New Round FPSO

FPSO Contractor Fleet Size

BP Scheihallion FPSO Offstation (youtube)

8. SPAR PLATFORM

SPAR is a deep-draft floating caisson, which is a hollow cylindrical structure similar to a very large buoy. Its four major systems are hull, moorings, topsides, and risers. The spar relies on a traditional mooring system (that is, anchor-spread mooring) to maintain its position. About 90 percent of the structure is underwater. Historically, spars were used as marker buoys, for gathering oceanographic data, and for oil storage. The spar design is now being used for drilling, production, or both. The distinguishing feature of a spar is its deep-draft hull, which produces very favorable motion characteristics compared to other floating concepts. Low motions and a protected centerwell also provide an excellent configuration for deepwater operations. Water depth capability has been stated by industry as ranging up to 10,000 ft.

The upper section is compartmentalized around a flooded centerwell containing the different type of risers. This section provides the buoyancy for the spar. The middle section is also flooded but can be economically configured for oil storage. The bottom section (keel) is compartmentalized to provide buoyancy during transport and to contain any field-installed, fixed ballast. Approximate hull diameter for a typical GOM spar is 130 feet, with an overall height, once deployed, of approximately 700 feet (with 90% of the hull in the water column).

The first Spars were based on the Classic design. This evolved into the Truss Spar by replacing the lower section of the caisson hull with a truss. The Truss Spar is divided into three distinct sections. The cylindrical upper section, called the “hard tank,” provides most of the in-place buoyancy for the Spar. The middle truss section supports the heave plates and provides separation between the keel tank and hard tank. The keel tank, also known as the “soft tank,” contains the fixed ballast and acts as a natural hang-off location for export pipelines and flowlines since the environmental influences from waves and currents and associated responses are less pronounced there than nearer the water line.

Wednesday, February 18, 2009

Oil and Gas Processing (Gas Section)